Frustrated that your visual inspection keeps flagging good parts while missing defects ?

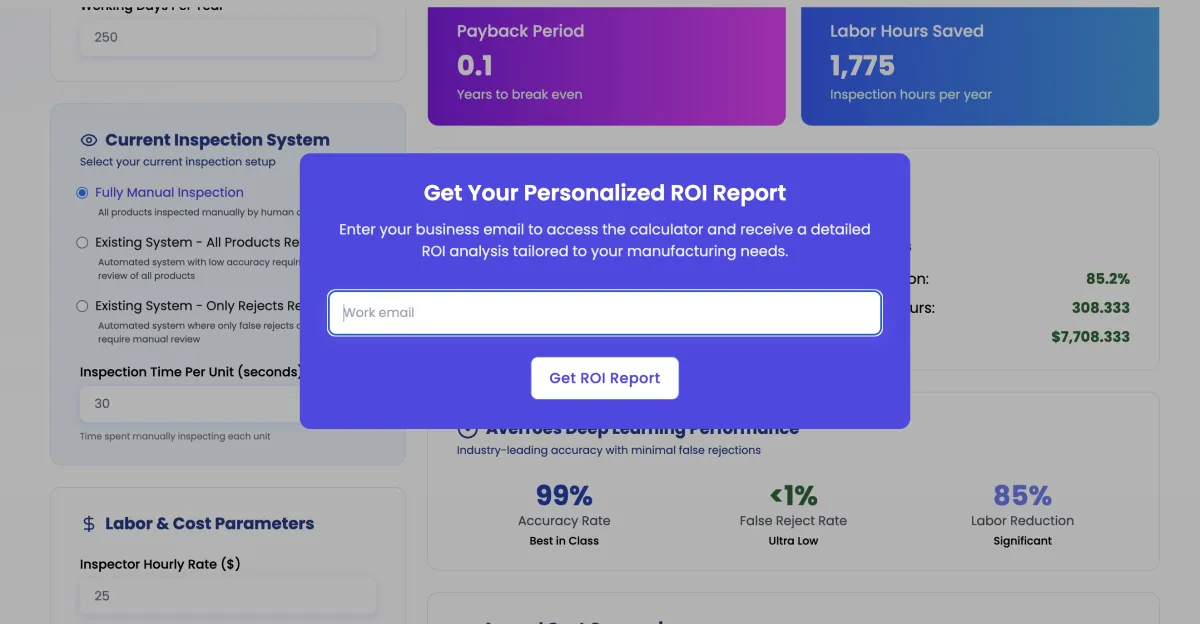

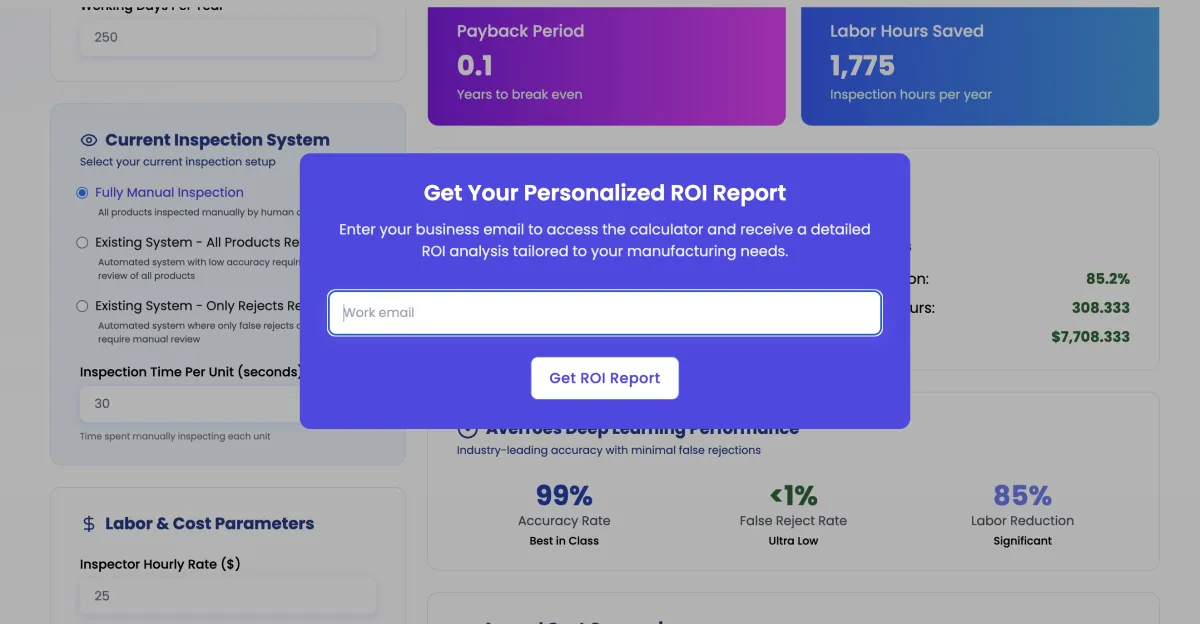

Enter your details to access the free 'Visual Inspection ROI Calculator' and compare your current setup with AI-powered visual inspection to see whether it can reduce false rejects, cut operator workload and increase yields for your business.

Frustrated that your visual inspection keeps flagging good parts while missing defects ?

Enter your details to access the free 'Visual Inspection ROI Calculator' and compare your current process with AI visual inspection to see how AI can reduce false rejects, cut operator workload and increase yields - without changing your existing setup.

Clients save hundreds of labour hours per month with Averroes AI

Accurate Defect Detection is typical for our clients

Reduction In False Rejects = Expected AI Improvement

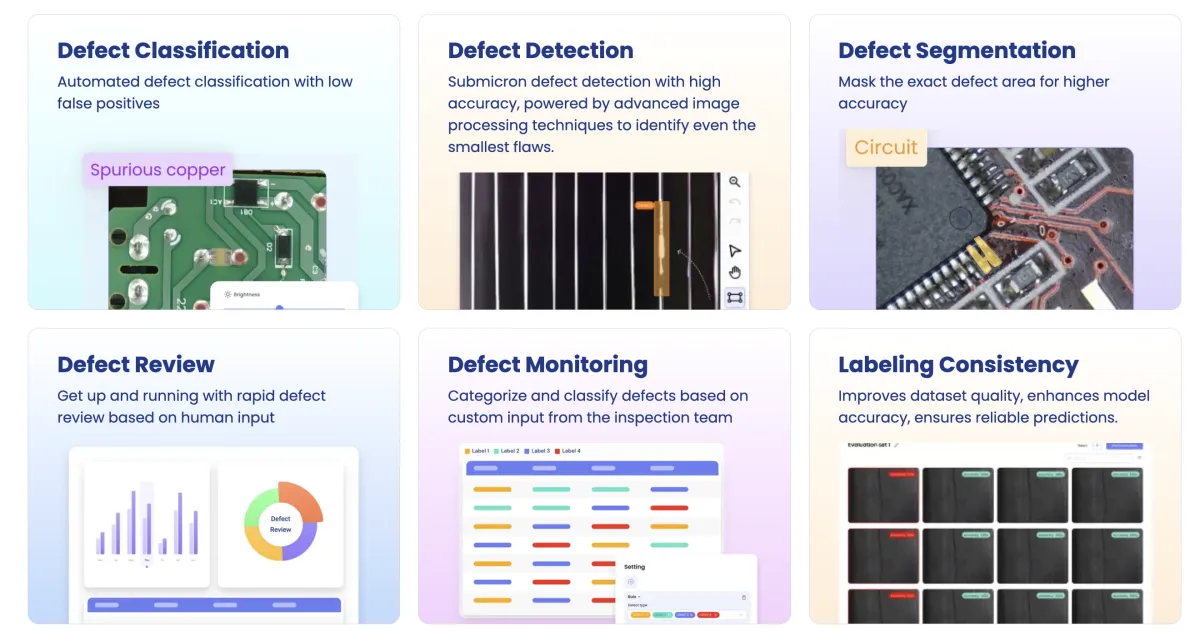

AI Visual Inspection Software That Spans All Verticals

The Leading Platform For AI Visual Inspection

If you have An existing Inspection system in place

Reduce false rejects and improve yield

Detect defects your AOI currently misses

Enhance accuracy with AI visual inspection

No additional hardware needed

If your visual Inspection process is manual

Cut inspection time by up to 70%

Eliminate human fatigue and inconsistency

Scale operations without adding headcount

Improve accuracy and throughput with AI

Here’s How It Works

How Averroes AI Improves Your Visual Inspection

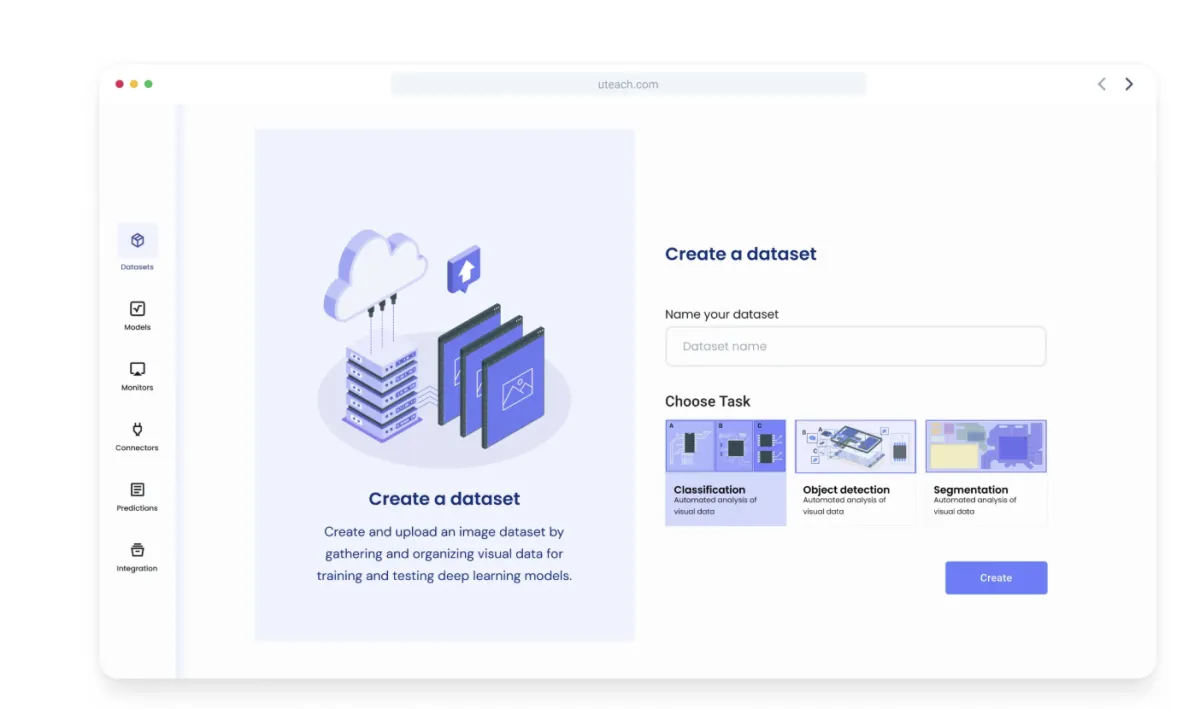

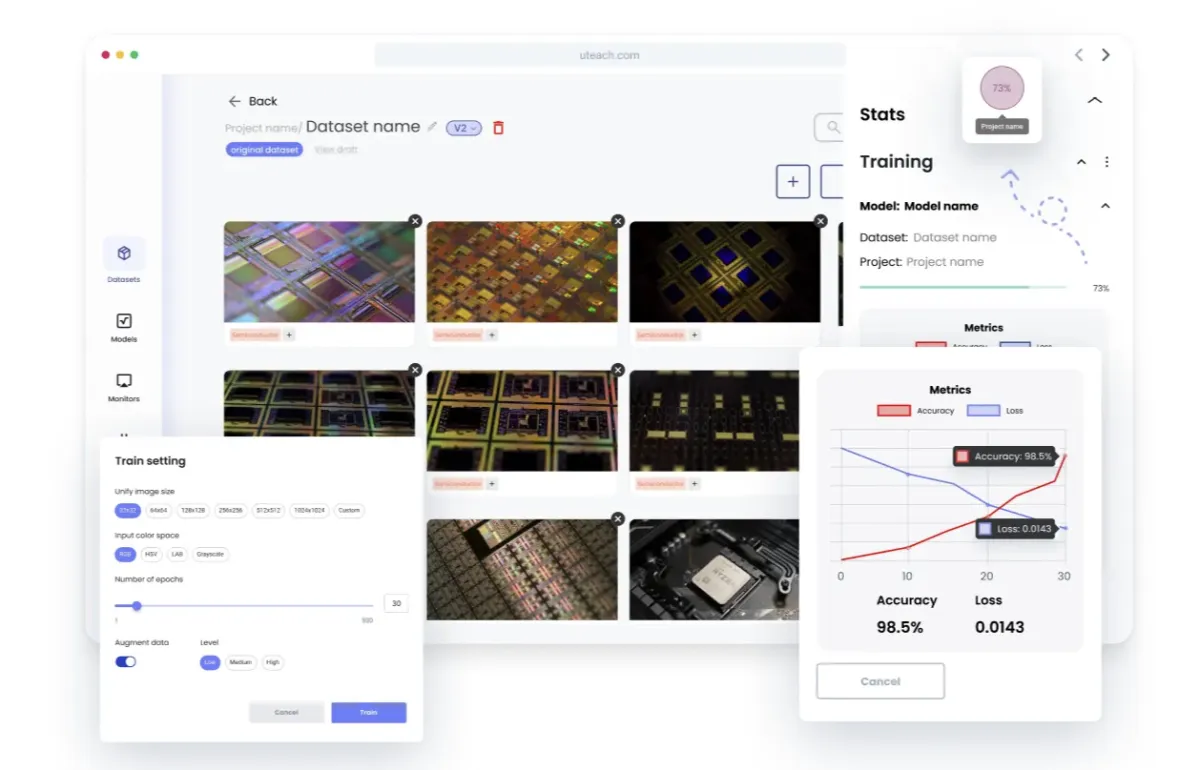

1. Create Your Image Dataset

Upload 20-40 images and label common defects, false rejects etc.

2. Train The AI Model Over Time

Give feedback to the software so that it can learn over time

3.Enjoy Improved Visual Inspection

Save hours of labour time and 99% visual inspection accuracy, with near zero false rejects

Visual Inspection Improvements For Clients Across All Industries

"We've experienced a remarkable 40-60% increase in submicron defect detection. Averroes has saved us over 300 hours/month/ app of labor and increased our productivity by more than 30%"

Automation Manager Semiconductor OEM

"Since implementing Averroes.ai in our facility, we've seen a remarkable increase in throughput, with zero line stoppages for calibration. The ability to adjust on the fly has boosted productivity and ensures that every product meets our stringent quality standards."

Production Manager

Food Processing Company

"Averroes' highly accurate AI application revolutionized our operations. They replaced costly, subjective manual inspection with their solution. We achieved superior defect detection, scaled our business, and now process 80,000 images in <20 hours."

Operation Manager

North America Solar O&M

Improve Your Visual Inspection With AI

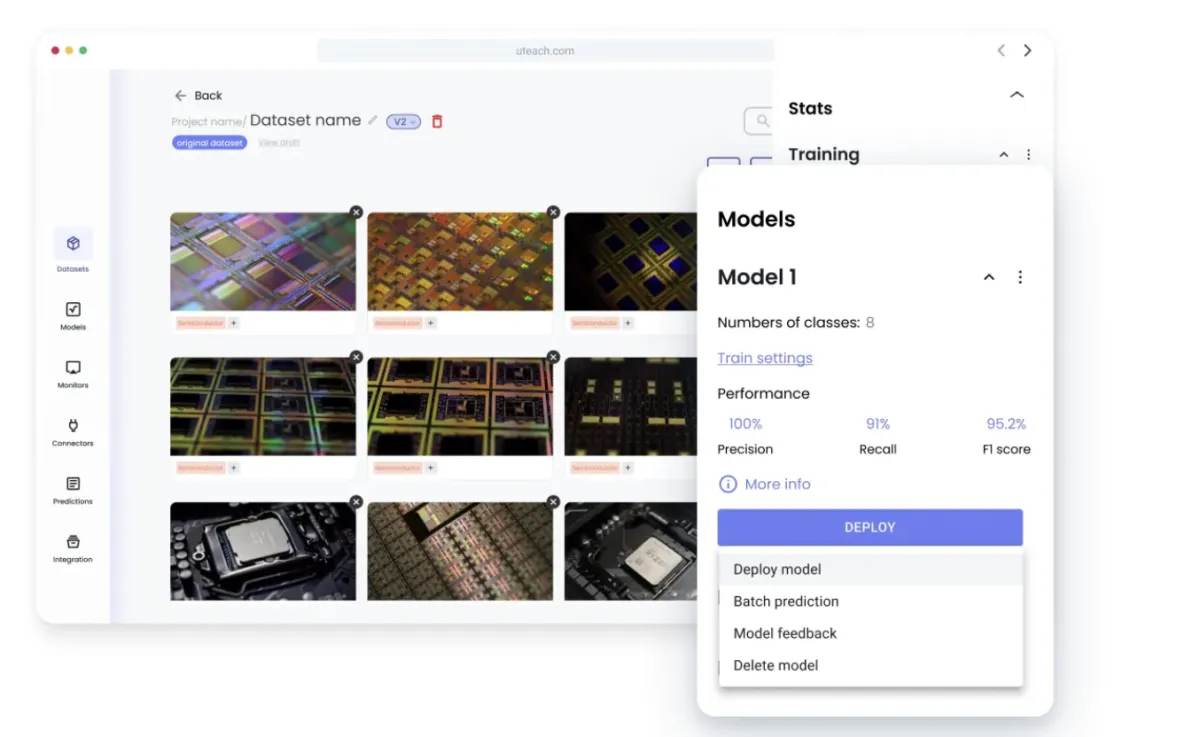

No Code Solution - Train and deploy custom AI models without any programming skills.

Cost-Optimized Solutions - Automate inspections to save 300+ hours monthly per application and boost product quality by 30%.

Proven Track Record - we've helped businesses like yours Automate inspections to save 300+ hours monthly per application and boost product quality by 30%.

Data & Vertical Agnostic - Our software spans industries from manufacturing to oil & Gas, food & Beverage, semiconductor, solar, electronics, drone and more

Industry-Leading Accuracy - Achieve 99%+ defect detection and 98.5%+ object detection rates with near-zero false positives.

Flexible Deployment Options – Whether on-premise for control or in the cloud for ease, our AI solutions integrate seamlessly into your existing detection system.

Improve The Accuracy Of Your

Visual Inspection With AI

Your Questions Answered

Does Averroes Require Us To Buy A New Camera Or Hardware

No. Averroes functions seamlessly on existing visual inspection equipment, leveraging advanced computer vision technology, whether it's KLA Tencor, AOI, or Onto equipment. No additional hardware purchase is needed.

Does Averroes Work With Existing Inspection Equipment?

Yes, Averroes works seamlessly with your existing equipment. Our AI model ingests and processes images produced by your current setup in real-time, enhancing its capabilities without interrupting your production line or requiring hardware modifications.

Is There Any Latency?

We process images in real-time the moment we receive them, with latency measured in microseconds.

What's Your Pricing Model?

We prioritize proving our value before discussing pricing. Each case is unique, so we prefer to learn more about your specific requirements first.

Can You Deploy The Model Completely Offline?

Yes, we offer an on-premise deployment option, allowing you to keep all your images and recipes within your own infrastructure.

How Many Images Do You Need For A Classification In The Upper 90s?

We require a minimal number of images - just 20-40 per class of defects.